Understanding the Heat of MAPP Gas Torches: A Comprehensive Guide

Related Articles: Understanding the Heat of MAPP Gas Torches: A Comprehensive Guide

Introduction

With great pleasure, we will explore the intriguing topic related to Understanding the Heat of MAPP Gas Torches: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Understanding the Heat of MAPP Gas Torches: A Comprehensive Guide

- 2 Introduction

- 3 Understanding the Heat of MAPP Gas Torches: A Comprehensive Guide

- 3.1 What is MAPP Gas and Why is its Temperature Important?

- 3.2 Factors Influencing MAPP Gas Torch Temperature

- 3.3 Understanding MAPP Gas Torch Temperature Ranges

- 3.4 Safety Precautions when Using MAPP Gas Torches

- 3.5 FAQs Regarding MAPP Gas Torch Temperature

- 3.6 Tips for Utilizing MAPP Gas Torch Temperature Effectively

- 3.7 Conclusion

- 4 Closure

Understanding the Heat of MAPP Gas Torches: A Comprehensive Guide

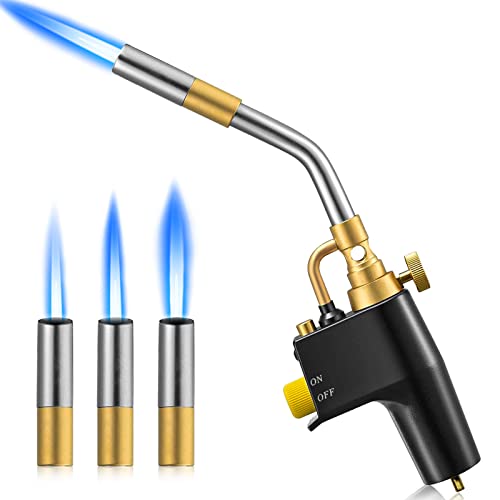

MAPP gas torches are renowned for their intense heat, making them indispensable tools in various applications. This guide delves into the intricacies of MAPP gas torch temperature, exploring its significance, factors influencing it, and the implications for different tasks.

What is MAPP Gas and Why is its Temperature Important?

MAPP gas, short for "methylacetylene-propadiene-propene," is a fuel gas mixture commonly used in torches. It boasts a higher energy content compared to propane, resulting in a significantly hotter flame. This high temperature is crucial for a variety of tasks, including:

- Brazing and Soldering: The intense heat allows for rapid melting of metals, enabling efficient brazing and soldering, particularly for thicker materials.

- Cutting and Welding: MAPP gas torches can be used for cutting and welding applications, particularly for light-duty tasks where the heat intensity of acetylene is not required.

- Heat Bending and Shaping: The focused heat of MAPP gas torches allows for precise heat bending and shaping of metal components.

- Thawing Frozen Pipes: The intense heat can quickly thaw frozen pipes, restoring water flow.

- Surface Preparation: MAPP gas torches can be used to remove paint, rust, and other coatings from surfaces, preparing them for subsequent treatments.

Factors Influencing MAPP Gas Torch Temperature

The temperature of a MAPP gas torch is not a fixed value, but rather a variable influenced by several factors:

- Gas Pressure: Higher gas pressure results in a greater volume of fuel and oxygen entering the torch, leading to a hotter flame.

- Air-Fuel Ratio: The ratio of air to fuel entering the torch affects the combustion process. A richer mixture (more fuel) generally produces a hotter flame, while a leaner mixture (more air) results in a cooler flame.

- Torch Tip Size: The size of the torch tip influences the flame size and intensity. Larger tips allow for greater gas flow, leading to a hotter flame.

- Ambient Temperature: Cooler ambient temperatures can slightly reduce the flame temperature, as the gas mixture cools before combustion.

Understanding MAPP Gas Torch Temperature Ranges

While the exact temperature of a MAPP gas torch can vary based on the factors mentioned above, a general understanding of the temperature ranges is crucial for selecting the appropriate tool for the task:

- Typical MAPP Gas Torch Temperature: The average temperature of a MAPP gas torch operating under standard conditions is approximately 3,600°F (1,982°C).

- Maximum Temperature: Under optimal conditions, with high gas pressure and a rich air-fuel mixture, a MAPP gas torch can reach temperatures exceeding 4,000°F (2,204°C).

Safety Precautions when Using MAPP Gas Torches

The high temperatures produced by MAPP gas torches necessitate strict safety precautions:

- Wear appropriate personal protective equipment (PPE): This includes heat-resistant gloves, safety glasses, and fire-retardant clothing.

- Ensure adequate ventilation: MAPP gas torches produce combustion byproducts, including carbon monoxide, which can be harmful in enclosed spaces.

- Keep flammable materials away: Always ensure that flammable materials are kept a safe distance from the torch.

- Never leave a running torch unattended: Always turn off the torch when not in use.

- Use proper handling techniques: Always handle the torch with care, and avoid dropping or mishandling it.

FAQs Regarding MAPP Gas Torch Temperature

1. What is the difference in temperature between MAPP gas and propane torches?

MAPP gas torches produce significantly higher temperatures than propane torches. While propane torches typically reach temperatures around 3,000°F (1,649°C), MAPP gas torches can achieve temperatures exceeding 3,600°F (1,982°C), making them ideal for applications requiring more intense heat.

2. Can MAPP gas torch temperature be adjusted?

Yes, MAPP gas torch temperature can be adjusted by manipulating the gas pressure and air-fuel ratio. Adjusting the pressure regulator on the gas cylinder controls the gas flow, while the torch’s mixing valve allows for fine-tuning of the air-fuel mixture.

3. How does the tip size affect MAPP gas torch temperature?

Larger torch tips allow for greater gas flow, leading to a hotter flame. However, it’s important to note that the tip size should be appropriate for the task. Using a tip too large can lead to excessive heat and damage to the workpiece.

4. Can MAPP gas torch temperature be measured?

Yes, MAPP gas torch temperature can be measured using a non-contact infrared thermometer. These devices measure the heat radiation emitted by the flame, providing an accurate reading of the temperature.

5. Is MAPP gas torch temperature consistent across all brands?

While the basic principles of MAPP gas torch operation remain the same, slight variations in temperature can occur between different brands due to factors like torch design, gas mixture composition, and manufacturing tolerances.

Tips for Utilizing MAPP Gas Torch Temperature Effectively

- Choose the right torch tip: Select a tip size appropriate for the task and material being worked on.

- Adjust gas pressure and air-fuel ratio: Experiment with these settings to achieve the desired flame temperature and intensity.

- Use a heat shield: Protect surrounding areas from excessive heat using a heat shield.

- Pre-heat the workpiece: For brazing and soldering applications, preheating the workpiece can improve heat transfer and reduce the risk of warping.

- Monitor the flame color: The flame color can indicate the temperature. A blue flame indicates a hotter temperature, while a yellow flame suggests a cooler temperature.

Conclusion

MAPP gas torches are versatile tools offering intense heat for a wide range of applications. Understanding the factors influencing MAPP gas torch temperature, including gas pressure, air-fuel ratio, and tip size, is crucial for selecting the appropriate tool and ensuring safe and effective operation. By employing the right techniques and observing safety precautions, MAPP gas torches can be utilized efficiently to perform tasks requiring high temperatures with precision and control.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Heat of MAPP Gas Torches: A Comprehensive Guide. We appreciate your attention to our article. See you in our next article!